Tips to Maintain Hydro Containers for Improved Miner’s Lifespan – Hydro containers serve an important role in many sectors, particularly mining, where they are used to store and manage water and other fluids. These containers are designed to be strong and resist extreme circumstances, but they still require regular maintenance to last longer and function properly. Taking proper care of hydro containers not only maintains the system safe but also extends the life of mining equipment and increases performance.

In this blog article, we will give some basic Tips for Maintain Hydro Containers to Improve Miner’s lifespans to ensure their performance, keep workers safe, and extend their total lifespan.

What are Hydro Containers?

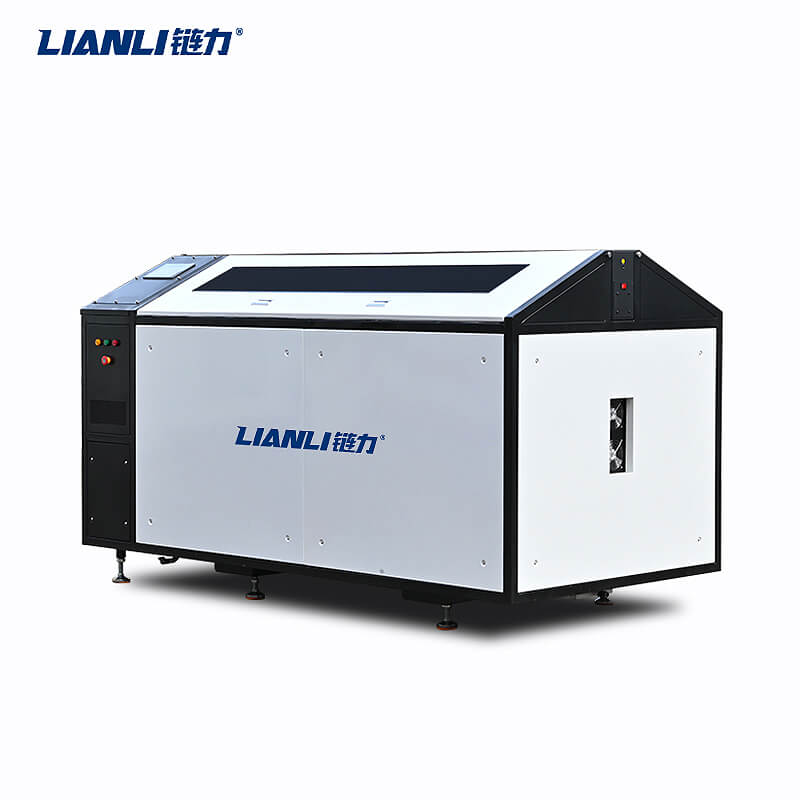

Let’s discuss the hydro containers before discussing the tips to maintain the Hydro containers. Hydro containers are also known as hydraulic fluid containers which hold liquid that is used in mining. These liquids are used to cool, lubricate, dust control, and power the mining machinery. They come in a variety of sizes, ranging from small portable tanks to enormous reservoirs capable of supporting whole mining operations. Hydro containers are often manufactured of strong, corrosion-resistant materials to endure the severe circumstances seen in mining, including intense temperatures, dampness, dust, and hard impacts.Here are Some of Tips to Maintain the Hydro Containers for Improved Miner’s Lifespan

1. Regular Check

The first step is to review the hydro containers frequently to maintain them in perfect condition. It detects the signs of wear, leaks, or damage before they evolve into a major issue.- Review the hydro container for any physical damage because if the mining tools work under pressure, it will result in leakage.

- Look for the infected fluid in the hydro container because rust or sediment can decrease the efficiency of the container.

- Always check the pipe links, valves, and seals to stop leaks because the efficiency of the system is decreased by even small leaks.

2. Clean and Control Contamination

Because hydraulic systems are so susceptible to contamination, any water, corrosion, or dirt can damage parts and cause the system to fail.- Clean the container regularly to eliminate dirt, dust, and waste, as these can lead to corrosion.

- Use high-quality filters to observe these pollutants before they enter the fluid. This will keep the container’s fluids clean.

3. Prevent corrosion in the hydro container.

Corrosion can occur due to contact with water, strong chemicals, or humidity. During Bitcoin mining, serious damage can occur in the hydro container due to corrosion. Over time, pollution can cause heavy damage to the operation of hydro containers.- You should use a protective layer on the Hydro container. The layers of corrosion-resistant mixtures can save the container from water, dampness, and chemicals.

- Be careful with the liquids in the container. Some chemicals can harm materials quickly. Use materials prepared for harsh substances if required.

4. Regular fluid monitoring.

The hydro container has a liquid called fluid that is vital for the proper working of Bitcoin mining. Here we explained about the inspection of this liquid –- Manage the level of fluid as required for the equipment. Low liquid levels can reduce the hydraulic, lubricating, and cooling effect of the hydro container.

- Determine the viscosity, acidity, and particle contamination of the liquid using the proper methods. Replace the poor-quality fluid to maintain the performance of the hydro container.

- The hydro container can face serious failure due to overheating. To help maintain the performance and avoid damage, keep an eye on the temperature of the fluid.

5. Appropriate Airflow

A major issue with hydro containers is the ventilation of gasses within the container during large-scale mining operations. The heating and cooling cycles of the fluid can cause gases to accumulate. Additionally, it could pose a safety risk and imbalances in pressure.- Make sure that the container has proper valves for releasing pressure. The purpose of these valves is to release excess pressure and protect the container from harm.

- The hydro container has enough airflow to avoid the accumulation of gas. To maintain proper pressure levels and air quality, use vent filters or pressure regulators in the hydro container.

- The pressure can be relieved from valves which helps to operate as intended in the case of an excessive pressure buildup.

6. Verify Correct Installation

Make sure that the hydro container is perfectly established. Wrong installation can decrease the working of the hydro container. Also, it can increase incidents like leaks, misalignments, and pressure on the container.- Verify that the container is set up on a proper level at the platform. If the hydro container is established at an irregular surface it can result in breaks.

- Make sure all pipe links, valves, and seals are tight during integration. Loose or poorly fit connections can be the reason for leaks and failures of containers.

7. Repair and Replace Worn Parts Quickly

Your hydro container can wear down in some places, even with frequent maintenance. It is necessary to adjust the broken parts and fix the worn ones to bypass any serious problems.- Check the gaskets and seals regularly. Broken gaskets can affect the pressure and efficiency of a hydro container and broken can lead to leakage of fluid.

- Review the pumps and valves repeatedly to handle wear and damage.