HOST ANTMINER S23 XP Hyd.: Why Water Cooling Is the Future of .Mining Hardware Cooling Performance

The relentless pursuit of higher hash rates and greater energy efficiency in cryptocurrency mining has pushed hardware capabilities to their limits. As miners deploy increasingly powerful Application-Specific Integrated Circuit (ASIC) devices like the ANTMINER S23 XP Hyd., managing the immense heat generated becomes a critical challenge. Traditional air cooling, while ubiquitous, struggles to keep pace with the thermal demands of next-generation miners. Enter liquid immersion cooling, a revolutionary technology rapidly emerging as the definitive solution for optimal mining hardware performance and longevity. The ANTMINER S23 XP Hyd. is not just another ASIC; it’s a harbinger of this liquid-cooled future, specifically designed to harness the unparalleled advantages of direct-to-chip water cooling.

The Thermal Challenge of High-Performance Miners: The Case of the ANTMINER S23 XP

The ANTMINER S23 XP represents the cutting edge of Bitcoin mining technology. Packing immense computational power into a compact form factor, it inevitably produces significant heat. While air cooling systems attempt to dissipate this heat using fans and heatsinks, they face inherent limitations. Air has a relatively low specific heat capacity, meaning it can absorb less heat per unit volume compared to liquids. This necessitates high airflow rates, leading to substantial noise pollution and dust accumulation, which can insulate components and reduce cooling efficiency over time. Furthermore, air cooling often results in uneven temperature distribution across the ASIC chips, creating hotspots that can throttle performance or shorten the device’s lifespan. For a powerhouse like the ANTMINER S23 XP, these limitations become bottlenecks to sustained peak operation.

Direct-to-Chip Water Cooling: How the ANTMINER S23 XP Hyd. Works

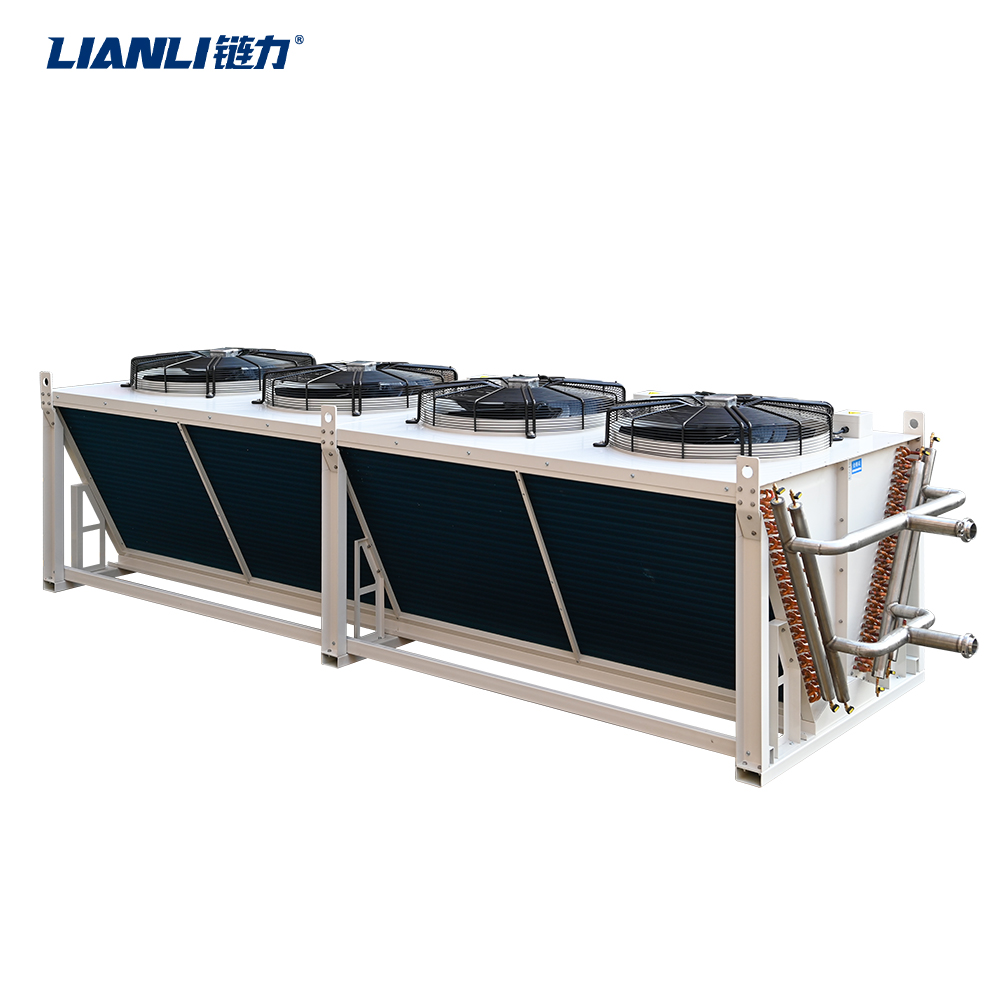

The ANTMINER S23 XP Hyd. model fundamentally rethinks thermal management. Instead of relying on air, it employs a direct-to-chip water cooling system. This involves routing coolant (typically a specialized dielectric fluid or water-glycol mix) through microchannels or cold plates directly attached to the heat-generating ASIC chips. The principle is simple: liquids are vastly more efficient at absorbing and transferring heat than air. The coolant flows directly over the primary heat source, rapidly absorbing thermal energy. This heated coolant is then pumped away from the miner to a heat exchanger (like a radiator), where the heat is dissipated into the ambient environment, and the cooled fluid is recirculated. This closed-loop system ensures consistent and highly efficient heat removal directly at the point of generation.

Unmatched Cooling Performance and Efficiency Gains

The benefits of this approach for the ANTMINER S23 XP Hyd. are profound. Firstly, temperature control is exceptional. Water cooling maintains the ASIC chips at significantly lower and more stable temperatures compared to air cooling. This eliminates hotspots and allows the miner to operate closer to its theoretical maximum performance for extended periods without thermal throttling. Secondly, energy efficiency (measured in J/TH) sees a dramatic improvement. Cooler chips are inherently more efficient; they require less electrical energy to perform the same computational work. Studies and real-world deployments consistently show liquid-cooled miners achieving lower J/TH ratios than their air-cooled counterparts. For the ANTMINER S23 XP Hyd., this translates directly into higher profitability by reducing the largest operational cost: electricity. Thirdly, noise reduction is remarkable. Eliminating the need for powerful, high-RPM fans results in near-silent operation, making liquid-cooled setups like the ANTMINER S23 XP Hyd. suitable for environments where noise is a concern.

Enhanced Reliability, Longevity, and Density

Beyond performance and efficiency, water cooling offers significant operational advantages. The stable, lower operating temperatures drastically reduce thermal stress on electronic components, leading to increased hardware reliability and extended lifespan. This is crucial for maximizing return on investment in expensive mining equipment. Furthermore, the superior heat transfer efficiency allows for much higher compute density. Liquid-cooled racks can pack miners much closer together since heat is removed via liquid pipes rather than relying on vast volumes of air movement. This enables the construction of more compact and scalable mining facilities. Finally, the sealed environment of many liquid cooling systems protects components from dust and corrosion, further enhancing longevity and reducing maintenance requirements.

Conclusion: The ANTMINER S23 XP Hyd. as a Blueprint for the Future

The evolution of mining hardware like the ANTMINER S23 XP Hyd. underscores a clear trend: water cooling is not merely an alternative; it is becoming the essential standard for high-performance, sustainable, and profitable mining operations. The limitations of air cooling are becoming increasingly apparent as ASIC power densities soar. Direct-to-chip water cooling, as implemented in the ANTMINER S23 XP Hyd., provides the superior thermal management required to unlock the full potential of modern mining rigs. It delivers unparalleled cooling performance, significant energy savings, quieter operation, enhanced reliability, and greater deployment flexibility. As the industry continues to prioritize efficiency and sustainability, the adoption of liquid cooling, exemplified by advanced models like the ANTMINER S23 XP Hyd., is poised to define the future landscape of cryptocurrency mining.

The relentless pursuit of higher hash rates and greater energy efficiency in cryptocurrency mining has pushed hardware capabilities to their limits. As miners deploy increasingly powerful Application-Specific Integrated Circuit (ASIC) devices like the ANTMINER S23 XP Hyd., managing the immense heat generated becomes a critical challenge. Traditional air cooling, while ubiquitous, struggles to keep pace with the thermal demands of next-generation miners. Enter liquid immersion cooling, a revolutionary technology rapidly emerging as the definitive solution for optimal mining hardware performance and longevity. The ANTMINER S23 XP Hyd. is not just another ASIC; it’s a harbinger of this liquid-cooled future, specifically designed to harness the unparalleled advantages of direct-to-chip water cooling.

The Thermal Challenge of High-Performance Miners: The Case of the ANTMINER S23 XP

The ANTMINER S23 XP represents the cutting edge of Bitcoin mining technology. Packing immense computational power into a compact form factor, it inevitably produces significant heat. While air cooling systems attempt to dissipate this heat using fans and heatsinks, they face inherent limitations. Air has a relatively low specific heat capacity, meaning it can absorb less heat per unit volume compared to liquids. This necessitates high airflow rates, leading to substantial noise pollution and dust accumulation, which can insulate components and reduce cooling efficiency over time. Furthermore, air cooling often results in uneven temperature distribution across the ASIC chips, creating hotspots that can throttle performance or shorten the device’s lifespan. For a powerhouse like the ANTMINER S23 XP, these limitations become bottlenecks to sustained peak operation.

Direct-to-Chip Water Cooling: How the ANTMINER S23 XP Hyd. Works

The ANTMINER S23 XP Hyd. model fundamentally rethinks thermal management. Instead of relying on air, it employs a direct-to-chip water cooling system. This involves routing coolant (typically a specialized dielectric fluid or water-glycol mix) through microchannels or cold plates directly attached to the heat-generating ASIC chips. The principle is simple: liquids are vastly more efficient at absorbing and transferring heat than air. The coolant flows directly over the primary heat source, rapidly absorbing thermal energy. This heated coolant is then pumped away from the miner to a heat exchanger (like a radiator), where the heat is dissipated into the ambient environment, and the cooled fluid is recirculated. This closed-loop system ensures consistent and highly efficient heat removal directly at the point of generation.

Unmatched Cooling Performance and Efficiency Gains

The benefits of this approach for the ANTMINER S23 XP Hyd. are profound. Firstly, temperature control is exceptional. Water cooling maintains the ASIC chips at significantly lower and more stable temperatures compared to air cooling. This eliminates hotspots and allows the miner to operate closer to its theoretical maximum performance for extended periods without thermal throttling. Secondly, energy efficiency (measured in J/TH) sees a dramatic improvement. Cooler chips are inherently more efficient; they require less electrical energy to perform the same computational work. Studies and real-world deployments consistently show liquid-cooled miners achieving lower J/TH ratios than their air-cooled counterparts. For the ANTMINER S23 XP Hyd., this translates directly into higher profitability by reducing the largest operational cost: electricity. Thirdly, noise reduction is remarkable. Eliminating the need for powerful, high-RPM fans results in near-silent operation, making liquid-cooled setups like the ANTMINER S23 XP Hyd. suitable for environments where noise is a concern.

Enhanced Reliability, Longevity, and Density

Beyond performance and efficiency, water cooling offers significant operational advantages. The stable, lower operating temperatures drastically reduce thermal stress on electronic components, leading to increased hardware reliability and extended lifespan. This is crucial for maximizing return on investment in expensive mining equipment. Furthermore, the superior heat transfer efficiency allows for much higher compute density. Liquid-cooled racks can pack miners much closer together since heat is removed via liquid pipes rather than relying on vast volumes of air movement. This enables the construction of more compact and scalable mining facilities. Finally, the sealed environment of many liquid cooling systems protects components from dust and corrosion, further enhancing longevity and reducing maintenance requirements.

Conclusion: The ANTMINER S23 XP Hyd. as a Blueprint for the Future

The evolution of mining hardware like the ANTMINER S23 XP Hyd. underscores a clear trend: water cooling is not merely an alternative; it is becoming the essential standard for high-performance, sustainable, and profitable mining operations. The limitations of air cooling are becoming increasingly apparent as ASIC power densities soar. Direct-to-chip water cooling, as implemented in the ANTMINER S23 XP Hyd., provides the superior thermal management required to unlock the full potential of modern mining rigs. It delivers unparalleled cooling performance, significant energy savings, quieter operation, enhanced reliability, and greater deployment flexibility. As the industry continues to prioritize efficiency and sustainability, the adoption of liquid cooling, exemplified by advanced models like the ANTMINER S23 XP Hyd., is poised to define the future landscape of cryptocurrency mining.

The relentless pursuit of higher hash rates and greater energy efficiency in cryptocurrency mining has pushed hardware capabilities to their limits. As miners deploy increasingly powerful Application-Specific Integrated Circuit (ASIC) devices like the ANTMINER S23 XP Hyd., managing the immense heat generated becomes a critical challenge. Traditional air cooling, while ubiquitous, struggles to keep pace with the thermal demands of next-generation miners. Enter liquid immersion cooling, a revolutionary technology rapidly emerging as the definitive solution for optimal mining hardware performance and longevity. The ANTMINER S23 XP Hyd. is not just another ASIC; it’s a harbinger of this liquid-cooled future, specifically designed to harness the unparalleled advantages of direct-to-chip water cooling.

The Thermal Challenge of High-Performance Miners: The Case of the ANTMINER S23 XP

The ANTMINER S23 XP represents the cutting edge of Bitcoin mining technology. Packing immense computational power into a compact form factor, it inevitably produces significant heat. While air cooling systems attempt to dissipate this heat using fans and heatsinks, they face inherent limitations. Air has a relatively low specific heat capacity, meaning it can absorb less heat per unit volume compared to liquids. This necessitates high airflow rates, leading to substantial noise pollution and dust accumulation, which can insulate components and reduce cooling efficiency over time. Furthermore, air cooling often results in uneven temperature distribution across the ASIC chips, creating hotspots that can throttle performance or shorten the device’s lifespan. For a powerhouse like the ANTMINER S23 XP, these limitations become bottlenecks to sustained peak operation.

Direct-to-Chip Water Cooling: How the ANTMINER S23 XP Hyd. Works

The ANTMINER S23 XP Hyd. model fundamentally rethinks thermal management. Instead of relying on air, it employs a direct-to-chip water cooling system. This involves routing coolant (typically a specialized dielectric fluid or water-glycol mix) through microchannels or cold plates directly attached to the heat-generating ASIC chips. The principle is simple: liquids are vastly more efficient at absorbing and transferring heat than air. The coolant flows directly over the primary heat source, rapidly absorbing thermal energy. This heated coolant is then pumped away from the miner to a heat exchanger (like a radiator), where the heat is dissipated into the ambient environment, and the cooled fluid is recirculated. This closed-loop system ensures consistent and highly efficient heat removal directly at the point of generation.

Unmatched Cooling Performance and Efficiency Gains

The benefits of this approach for the ANTMINER S23 XP Hyd. are profound. Firstly, temperature control is exceptional. Water cooling maintains the ASIC chips at significantly lower and more stable temperatures compared to air cooling. This eliminates hotspots and allows the miner to operate closer to its theoretical maximum performance for extended periods without thermal throttling. Secondly, energy efficiency (measured in J/TH) sees a dramatic improvement. Cooler chips are inherently more efficient; they require less electrical energy to perform the same computational work. Studies and real-world deployments consistently show liquid-cooled miners achieving lower J/TH ratios than their air-cooled counterparts. For the ANTMINER S23 XP Hyd., this translates directly into higher profitability by reducing the largest operational cost: electricity. Thirdly, noise reduction is remarkable. Eliminating the need for powerful, high-RPM fans results in near-silent operation, making liquid-cooled setups like the ANTMINER S23 XP Hyd. suitable for environments where noise is a concern.

Enhanced Reliability, Longevity, and Density

Beyond performance and efficiency, water cooling offers significant operational advantages. The stable, lower operating temperatures drastically reduce thermal stress on electronic components, leading to increased hardware reliability and extended lifespan. This is crucial for maximizing return on investment in expensive mining equipment. Furthermore, the superior heat transfer efficiency allows for much higher compute density. Liquid-cooled racks can pack miners much closer together since heat is removed via liquid pipes rather than relying on vast volumes of air movement. This enables the construction of more compact and scalable mining facilities. Finally, the sealed environment of many liquid cooling systems protects components from dust and corrosion, further enhancing longevity and reducing maintenance requirements.

Conclusion: The ANTMINER S23 XP Hyd. as a Blueprint for the Future

The evolution of mining hardware like the ANTMINER S23 XP Hyd. underscores a clear trend: water cooling is not merely an alternative; it is becoming the essential standard for high-performance, sustainable, and profitable mining operations. The limitations of air cooling are becoming increasingly apparent as ASIC power densities soar. Direct-to-chip water cooling, as implemented in the ANTMINER S23 XP Hyd., provides the superior thermal management required to unlock the full potential of modern mining rigs. It delivers unparalleled cooling performance, significant energy savings, quieter operation, enhanced reliability, and greater deployment flexibility. As the industry continues to prioritize efficiency and sustainability, the adoption of liquid cooling, exemplified by advanced models like the ANTMINER S23 XP Hyd., is poised to define the future landscape of cryptocurrency mining.

The relentless pursuit of higher hash rates and greater energy efficiency in cryptocurrency mining has pushed hardware capabilities to their limits. As miners deploy increasingly powerful Application-Specific Integrated Circuit (ASIC) devices like the ANTMINER S23 XP Hyd., managing the immense heat generated becomes a critical challenge. Traditional air cooling, while ubiquitous, struggles to keep pace with the thermal demands of next-generation miners. Enter liquid immersion cooling, a revolutionary technology rapidly emerging as the definitive solution for optimal mining hardware performance and longevity. The ANTMINER S23 XP Hyd. is not just another ASIC; it’s a harbinger of this liquid-cooled future, specifically designed to harness the unparalleled advantages of direct-to-chip water cooling.

The Thermal Challenge of High-Performance Miners: The Case of the ANTMINER S23 XP

The ANTMINER S23 XP represents the cutting edge of Bitcoin mining technology. Packing immense computational power into a compact form factor, it inevitably produces significant heat. While air cooling systems attempt to dissipate this heat using fans and heatsinks, they face inherent limitations. Air has a relatively low specific heat capacity, meaning it can absorb less heat per unit volume compared to liquids. This necessitates high airflow rates, leading to substantial noise pollution and dust accumulation, which can insulate components and reduce cooling efficiency over time. Furthermore, air cooling often results in uneven temperature distribution across the ASIC chips, creating hotspots that can throttle performance or shorten the device’s lifespan. For a powerhouse like the ANTMINER S23 XP, these limitations become bottlenecks to sustained peak operation.

Direct-to-Chip Water Cooling: How the ANTMINER S23 XP Hyd. Works

The ANTMINER S23 XP Hyd. model fundamentally rethinks thermal management. Instead of relying on air, it employs a direct-to-chip water cooling system. This involves routing coolant (typically a specialized dielectric fluid or water-glycol mix) through microchannels or cold plates directly attached to the heat-generating ASIC chips. The principle is simple: liquids are vastly more efficient at absorbing and transferring heat than air. The coolant flows directly over the primary heat source, rapidly absorbing thermal energy. This heated coolant is then pumped away from the miner to a heat exchanger (like a radiator), where the heat is dissipated into the ambient environment, and the cooled fluid is recirculated. This closed-loop system ensures consistent and highly efficient heat removal directly at the point of generation.

Unmatched Cooling Performance and Efficiency Gains

The benefits of this approach for the ANTMINER S23 XP Hyd. are profound. Firstly, temperature control is exceptional. Water cooling maintains the ASIC chips at significantly lower and more stable temperatures compared to air cooling. This eliminates hotspots and allows the miner to operate closer to its theoretical maximum performance for extended periods without thermal throttling. Secondly, energy efficiency (measured in J/TH) sees a dramatic improvement. Cooler chips are inherently more efficient; they require less electrical energy to perform the same computational work. Studies and real-world deployments consistently show liquid-cooled miners achieving lower J/TH ratios than their air-cooled counterparts. For the ANTMINER S23 XP Hyd., this translates directly into higher profitability by reducing the largest operational cost: electricity. Thirdly, noise reduction is remarkable. Eliminating the need for powerful, high-RPM fans results in near-silent operation, making liquid-cooled setups like the ANTMINER S23 XP Hyd. suitable for environments where noise is a concern.

Enhanced Reliability, Longevity, and Density

Beyond performance and efficiency, water cooling offers significant operational advantages. The stable, lower operating temperatures drastically reduce thermal stress on electronic components, leading to increased hardware reliability and extended lifespan. This is crucial for maximizing return on investment in expensive mining equipment. Furthermore, the superior heat transfer efficiency allows for much higher compute density. Liquid-cooled racks can pack miners much closer together since heat is removed via liquid pipes rather than relying on vast volumes of air movement. This enables the construction of more compact and scalable mining facilities. Finally, the sealed environment of many liquid cooling systems protects components from dust and corrosion, further enhancing longevity and reducing maintenance requirements.

Conclusion: The ANTMINER S23 XP Hyd. as a Blueprint for the Future

The evolution of mining hardware like the ANTMINER S23 XP Hyd. underscores a clear trend: water cooling is not merely an alternative; it is becoming the essential standard for high-performance, sustainable, and profitable mining operations. The limitations of air cooling are becoming increasingly apparent as ASIC power densities soar. Direct-to-chip water cooling, as implemented in the ANTMINER S23 XP Hyd., provides the superior thermal management required to unlock the full potential of modern mining rigs. It delivers unparalleled cooling performance, significant energy savings, quieter operation, enhanced reliability, and greater deployment flexibility. As the industry continues to prioritize efficiency and sustainability, the adoption of liquid cooling, exemplified by advanced models like the ANTMINER S23 XP Hyd., is poised to define the future landscape of cryptocurrency mining.