Data Center Liquid Cooling System

Designed to meet the growing demands of high-performance computing, our liquid cooling solution offers superior heat management, reduced energy consumption, and optimized server performance. By utilizing a closed-loop liquid cooling system, we ensure your data center operates at lower temperatures, improving reliability and extending the lifespan of your critical equipment. With a scalable, eco-friendly design, our system is the ideal choice for businesses looking to maximize efficiency and reduce operational costs while ensuring peak performance in their data center.

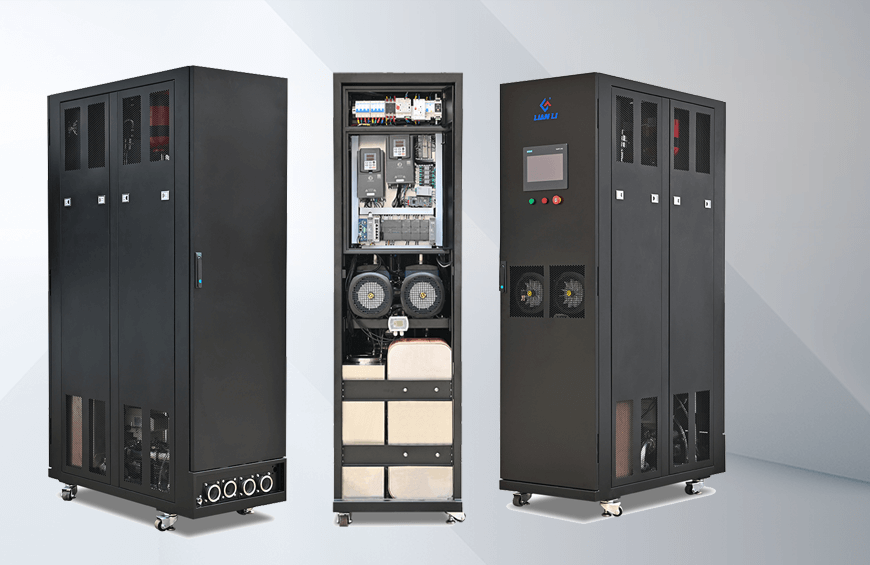

IDC Coolant distribution unit

Compatible with liquid-cooled servers and Bitcoin mining, using dual-pump redundancy solutions, built-in high-power heat exchangers, 3 high-precision filters, using degassing tank technology, faster pipeline exhaust. Using Siemens PLC, real-time synchronization of local data in the cloud, supporting remote monitoring and control.

IDC Coolant distribution unit

Equipped with ultra-high power heat exchanger and PDU, it can meet the overclocking of 30 miners at the same time. The intelligent CDU can monitor the oil temperature, water temperature, flow and other operating conditions in real time locally and on the cloud.

65kw IDC Embedded CDU

4U size, compatible with traditional server racks, built-in redundant dual pumps, redundant power supplies, filters, high-precision sensors, and heat exchangers

For more power please contact

This is an upgraded version. On the basis of the original one, a Siemens remote control system is added, which has a wider data surface monitoring function, and the cabinet door opening and closing method is replaced by a stepper motor instead of the original manual method.

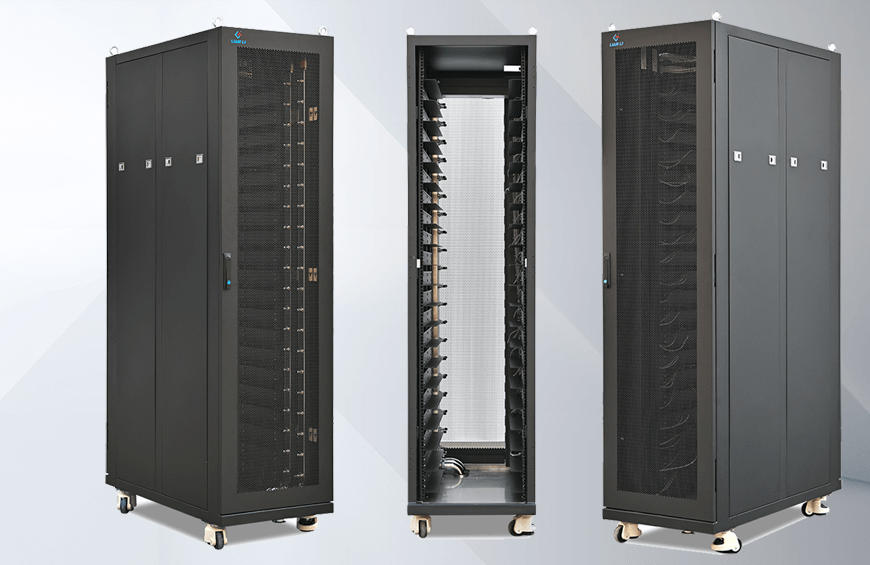

48U IDC server rack

The first choice for small-scale home mining solutions, it has a beautiful appearance, supports dual-mode cooling (dry cooler and cooling tower), and has a built-in temperature measurement and control system. When the coolant exceeds the set temperature, the system will automatically turn on power-off protection.

48U IDC server rack

The first choice for small-scale home mining solutions, it has a beautiful appearance, supports dual-mode cooling (dry cooler and cooling tower), and has a built-in temperature measurement and control system. When the coolant exceeds the set temperature, the system will automatically turn on power-off protection.

For more sizes please contact

Compact size, equipped with 6KW dry cooler, built-in temperature monitoring safety system, compatible with air-cooled miners,

Please contact us for customization

The most cost-effective choice, and capacity expansion can be achieved through parallel connection

Core Difference Comparison: Liquid-Cooled vs Air-Cooled Data Centers

Understanding the difference between liquid cooling and air cooling is essential when choosing the right data center cooling system. Below is a detailed comparison highlighting performance, efficiency, and deployment considerations.

| Category | Liquid-Cooled Data Center | Air-Cooled Data Center |

|---|---|---|

| Cooling Medium | Liquids (e.g., water, mineral oil, fluorinated fluid) | Air |

| Cooling Method | Liquid directly contacts the heat source or transfers heat via a cold plate | Forced air circulation using air conditioning and fans |

| Cooling Efficiency | Very high — liquids have 1,000–3,000× the heat capacity of air | Low — depends on air velocity and temperature gradient |

| Applicable Scenarios | High-density computing (AI, HPC, GPU clusters) | Medium to low-density servers (traditional IT workloads) |

| Energy Consumption | Significantly reduced (PUE as low as 1.05–1.2) | Higher (PUE typically 1.5–2.0) |

| Space Utilization | Compact design, supports high-density deployment | Requires more space for air circulation |

| Noise Level | Low — minimizes fan usage | High — relies on large air conditioners and fans |

| Environmental Dependency | Low — stable performance regardless of ambient temperature | High — efficiency drops in hot environments, relies on cool outside air |

Core Advantages of Liquid Cooling Technology

1. Ultra-High Heat Dissipation Efficiency

Superior Thermal Conductivity: Liquid has a much higher heat transfer capacity than air, allowing it to rapidly remove heat from high-power chips such as CPUs and GPUs, preventing thermal throttling and maintaining peak performance.

Cold Plate Liquid Cooling: Uses a metal cold plate to directly cool the chip surface, ideal for applications with localized high heat flux density.

Immersion Liquid Cooling: Servers are fully submerged in non-conductive coolant, enabling full-surface heat dissipation and stable operation under ultra-high-density deployments.

2. Significant Energy Savings and Reduced Power Consumption

Lower Dependence on Air Conditioning: Liquid cooling minimizes the need for traditional HVAC systems, drastically reducing power draw. Power Usage Effectiveness (PUE) can reach as low as 1.05, compared to ≥1.5 in air-cooled systems.

Real-World Example: Google reported a 40% reduction in cooling energy consumption after implementing large-scale liquid cooling in its data centers.

3. Improved Space Utilization

Compact and Efficient Layout: Liquid cooling systems eliminate bulky air ducts, allowing racks to be more densely arranged. This design increases computing power per unit area by 30–50%, maximizing space efficiency in modern data centers.

4. Stronger Environmental Adaptability

Resilient to Harsh Conditions: Liquid cooling is not limited by ambient air temperature and can operate efficiently in hot or arid regions. This reduces dependency on natural cold sources and external climate conditions.

5. Noise Reduction and System Stability

Quieter Operation: By significantly reducing fan usage, noise levels drop by 20–35 decibels, creating a quieter and more comfortable working environment.

Enhanced Reliability: The stable thermal properties of liquid help maintain consistent operating temperatures, reducing equipment failure rates caused by temperature fluctuations.

6. Ready for Future Technology Evolution

Built for High-Power Chips: Liquid cooling supports the increasing power demands of next-generation processors and AI accelerators, such as GPU clusters and NVIDIA H100 chips exceeding 700W per unit.

Future-Proof Design: Ideal for AI, HPC, and edge computing environments that require high-density, high-performance, and sustainable thermal management.

Why Liquid Cooling Leads the Future of Data Center Efficiency?

Liquid cooling delivers superior thermal performance, lower energy costs, and compact deployment, making it the go-to choice for next-generation data centers that power AI, blockchain, and high-performance computing.