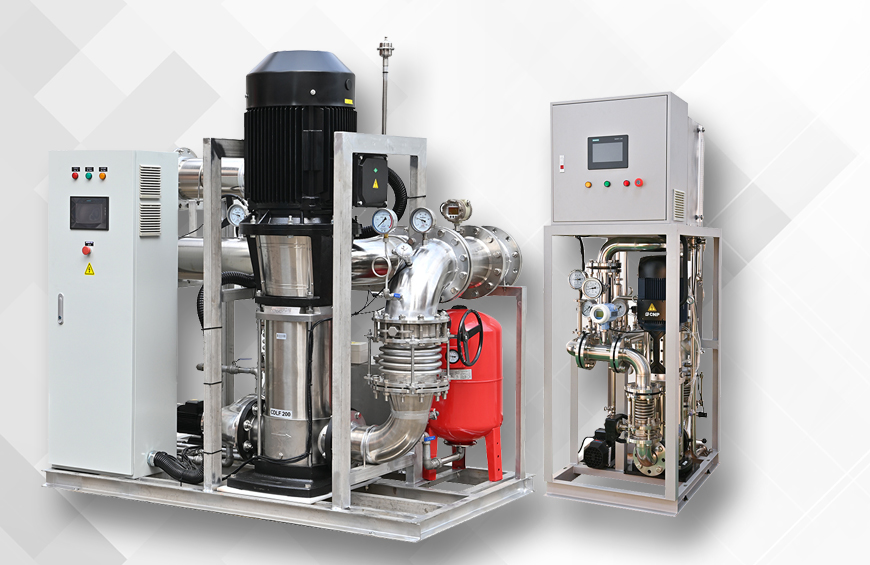

200-1000KW CDU (Coolant Distribution Unit )

Coolant Distribution Unit Independently Developed By LianLi

Applicable to liquid cooling systems of data centers or high-performance computing equipment. Responsible for the distribution of cold sources and the utilization of heat sources. Functions: automatic make-up water , pressure monitoring, automatic pressure relief, power monitoring, temperature monitoring, automatic frequency modulation, flow monitoring, water level monitoring, remote control,

Coolant distribution unit independently developed by LIANLI

Applicable to liquid cooling systems of data centers or high-performance computing equipment. Responsible for the distribution of cold sources and the utilization of heat sources. Functions: automatic make-up water , pressure monitoring, automatic pressure relief, power monitoring, temperature monitoring, automatic frequency modulation, flow monitoring, water level monitoring, remote control,

Optional heating function

Hydro miners have difficulty starting up in cold areas with low water temperatures. This CDU has a built-in heating device and controls the local return of coolant through an electric three-way valve, which can quickly heat up and start the miner.

Optional dual pump redundancy

There are two high-performance centrifugal pumps of famous brands built in, which are controlled by programs and work in turns to minimize the loss of parts. When one of them fails, the other one will immediately take over.

Please contact me for more customized needs

Coolant Distribution Unit

The Lianli Coolant Distribution Unit (CDU) is a specialized component designed to enhance the efficiency of custom water cooling loops in hydro crypto currency mining hardware. Coolant Distribution Unit is a device used in the liquid cooling system of the data center or High performance computing. It is mainly composed of a circulating pump, a frequency converter, an electronic control unit, a monitoring sensor unit, connecting pipes and valves, and more.

CDU is the core of the liquid cooling scheme. It is responsible for the use of cold sources, heat dissipation allocation with heat sources, and can be configured as needed to maximize heat dissipation.

Key Features and Functions of CDU

1.Efficient Cooling Distribution: The Standard CDU is engineered to provide efficient cooling distribution for your hydro cooling ASIC miners. Equipped with a powerful circulating pump, the CDU system ensures a consistent flow of coolant, effectively dissipating heat and maintaining optimal operating temperatures for your mining equipment.

2.Automatic Water Replenishment: Enjoy hassle-free water management with the CDU system’s automatic water replenishment function. This feature ensures a continuous and stable water supply to your mining setup, eliminating the need for manual intervention and allowing you to focus on maximizing your mining efficiency.

3.Comprehensive Monitoring and Control: Stay in full control of your mining operation with the CDU system. The CDU system incorporates a range of monitoring and control functions to optimize your setup’s performance. From pressure sensing and automatic pressure relief to power monitoring, water temperature monitoring, automatic frequency modulation, and flow rate monitoring, you have complete visibility and control over critical parameters.

4. Control Tower PLC Adjustment: The CDU system features a control tower with PLC adjustment capabilities, allowing you to fine-tune and customize various parameters to meet the specific requirements of your mining setup. Take advantage of precise control and optimization to maximize the efficiency of your cooling system.

5. Remote Control System: Manage your mining setup with ease using the CDU system’s remote control capabilities. With a user-friendly remote control system, you can monitor and control your setup from anywhere. Access real-time data, receive notifications for any abnormalities via email, and make adjustments remotely for enhanced convenience and operational efficiency.

6. Robust Safety Measures: The CDU system prioritizes the safety of your mining equipment. It includes environmental temperature monitoring, water level conduction, abnormal mailbox alarm, and other safety features to safeguard your setup and ensure worry-free operation.

How Do CDU Units Work?

Coolant distribution units create an isolated secondary loop separated from the chilled water supply, enabling strict containment management and precise control of the liquid cooling system’s temperature, pressure, and flow rate. The CDU maintains the secondary loop supply temperature above the dew point of the data centre, preventing condensation and ensuring 100% sensible cooling.

Whether self-contained in-row CDUs or integrated in-rack CDUs, liquid-to-liquid coolant distribution units must be connected to the existing FWS supported by a heat exchanger that facilitates the transfer of heat out of a CDU.

For a liquid-to-air system, the CDU transfers the heat to the ambient supply utilizing a heat exchange coil design within the CDU.

CDUs are equipped with filters, typically 50 microns, to keep the water supply contaminant and debris free and to protect the server cold plate integrity and performance. Most systems feature integrated leak detection, intelligent flow monitoring devices, and alarm features to maintain system performance and protect data center equipment.

Benefits of Lianli’s Coolant Distribution Unit

Efficient Cooling

CDUs are more compact and flexible than traditional air conditioning systems. Because of their smaller size and weight, they can also be located closer to the cooled server, which requires less energy because they don’t need to distribute coolant over an entire room or building.

CDUs can achieve significant energy savings compared to traditional air conditioners or chillers by reducing power consumption while increasing system uptime and reliability – leading to lower operating costs in the long run.

Precise Temperature Control

CDUs can also help protect data centers from potential damage due to overheating. Due to specialized controllers, CDUs can maintain precise temperatures from -20°C (-4˚F) up to a maximum of +70°C (158˚F), making it easier for data center operators to customize their requirements. This prevents component failure or even fire hazards.

Redundancy

Redundant pumps and power inputs ensure continuous operation and that precise temperature, flow rate, and pressure are continuously maintained, thus ensuring uptime and increasing reliability.

Wrapping Up!

Coolant Distribution Units (CDUs) are essential in data centers with high-density applications providing close controlled coolant delivery and precise control of the liquid cooling system. They help manage heat loads, reduce power consumption, and increase efficiency and reliability through redundancy. CDUs also promote environmental sustainability by decreasing carbon dioxide emissions.

FAQs on Coolant Distribution Unit

1. Why do we need two loops for liquid cooling?

We need two loops for liquid cooling –

- For high quality facility water which is not available in most Data Centers – a secondary loop is required between the CDU and the cold plates. This helps achieves the highest quality of water while keeping WUE low.

- Precision control of the coolant

- The CDU can control the pressure, flow and temperature.

2. What is the function of coolant distribution unit?

A CDU is designed to manage high heat loads for accelerated compute and high-density data center environments, providing critical cooling capacity and heat removal functions. The CDU provides controlled, contaminant-free coolant for heat exchangers, direct-to-chip, and immersion cooling devices.

3. What is a CDU system in a data center?

Coolant distribution units (CDUs) cool, distribute, and regulate fluid within a liquid cooling system. By optimizing both individual components and how they work together, Boyd builds efficient, high capacity CDUs in dense volumes.